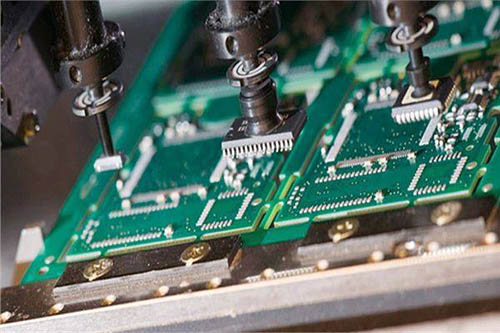

Manufacturing Advantages of Rigid PCB Printed Circuit Boards

A rigid PCB printed circuit board is a sturdy board that is not easily deformed. We cannot bend them or deform them. It is very difficult to fold or modify them after manufacture. Rigid PCB printed circuit boards are made of a solid substrate and have copper traces.

They also include component layouts that allow active and passive components to be soldered by automated or manual techniques. Rigid PCBs offer many advantages when used in commercial and industrial electronic systems:

1. Rigid PCB printed circuit boards can be used in any device without having to design the device according to the specifications of the PCB.

2. Compact and lightweight, with smaller size.

3. Can design contactless crimp or connector products that are reliable for high-end applications.

4. Because of their smaller number of interconnections, there is less chance of circuit failure.

5. Due to its thermally stable structure, rigid PCB printed circuit boards can withstand extreme temperatures. This advanced performance makes it a suitable choice for aerospace and military applications.

6. Requires less material to manufacture. Therefore, the cost of material procurement and manufacturing is reduced.

7. Rigid PCB has good resistance to UV rays, anti-corrosion oils and harsh chemicals. Therefore, it can be used in marine applications.

8. It can be designed for surface mounting on both sides.

9. Can be customized to meet special T industry requirements.

10. Can withstand vibration, high shock and other harsh conditions.