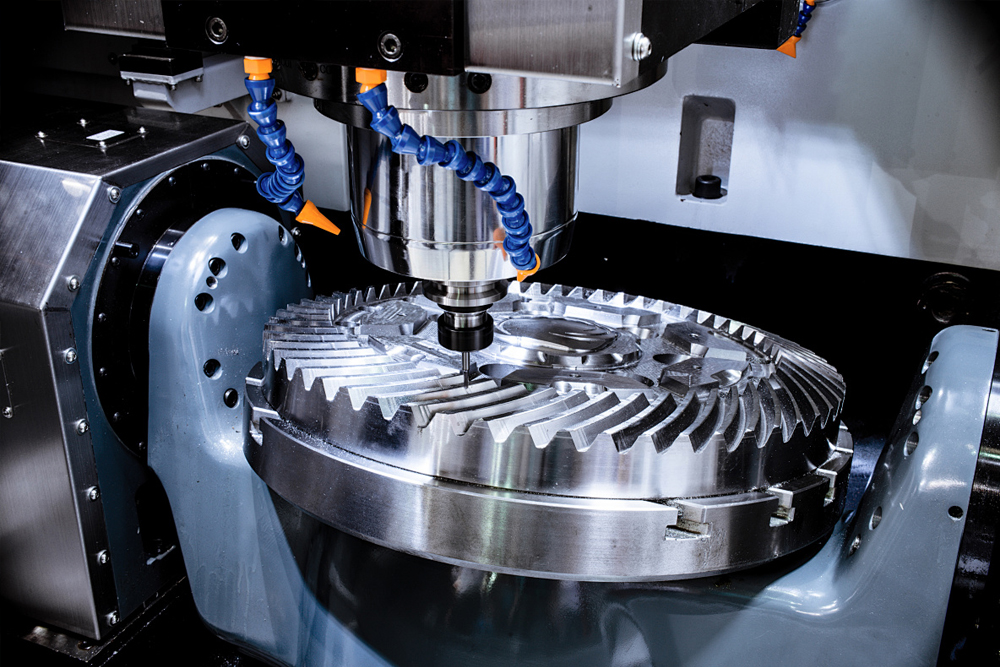

CNC Machining Methods

A workpiece is rotated while a stationary cutting tool removes material, producing cylindrical shapes. Commonly used for creating shafts, rings, and other rotational components.

Involves rotating a cutting tool against a stationary workpiece to remove material. Ideal for complex shapes, including contours and features like slots, pockets, and holes.

Utilizes drill bits to create holes in metal parts. Often used to create mounting holes or to prepare for further machining operations.

Uses electrical discharges (sparks) to erode material from a workpiece. Common in mold making, tool and die work, and complex geometries.

Uses a high-temperature plasma arc to cut through metal sheets. Best for thicker materials and often used in fabricating large components in the automotive and aerospace industries.

Uses a focused laser beam to melt or vaporize metal. Excellent for intricate designs and high precision in cutting thin sheets of metal.

Uses high-pressure water mixed with abrasive materials to cut through metal. Effective for various materials, including those sensitive to high heat, as it does not produce thermal distortion.

Some CNC setups now incorporate additive processes to create metal parts layer by layer. Useful for rapid prototyping, tooling, and complex geometries that traditional machining may struggle with.

Advantages of Metal CNC Machining

The advantages of CNC machining are significant. It provides exceptional precision and repeatability, ensuring highly accurate and consistent parts. The process is highly automated, which boosts efficiency, lowers labor costs, and minimizes human error. Furthermore, CNC machining is remarkably flexible. A single machine can produce various parts by simply changing the digital program, making it ideal for both prototyping and full-scale production.

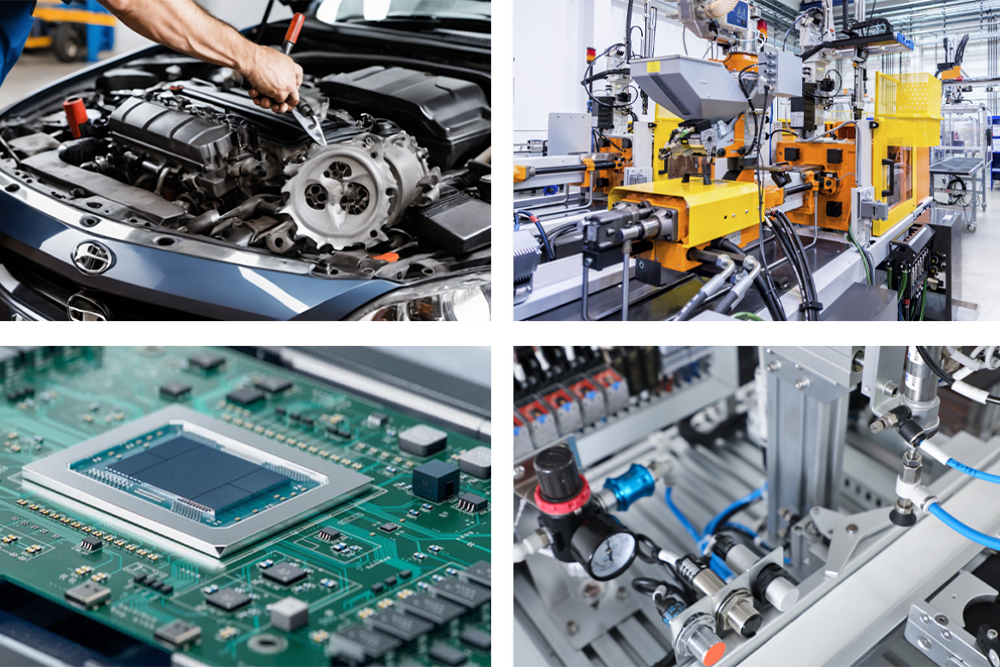

Application Of Metal CNC Machining

We have delivered exceptional metal machining parts for thousands of clients across diverse industries, including electronics, medical devices, motorcycles and bicycles, industrial machinery, marine, robotics, aerospace, sporting goods and telecommunications. Our expertise and strict quality standards ensure that each part perfectly meets our clients’ needs. Choose us as your reliable partner to elevate your business!

We specialize in multi-axis CNC machining (3-axis, 4-axis, 5-axis) and can achieve standard tolerances of ±0.02mm (±0.001"), with tighter tolerances available upon request. We work with a wide range of metals and engineering plastics.

We accept STEP, IGES, X_T, SLDPRT, and DWG/DXF files. 2D drawings with critical dimensions and tolerances are highly recommended alongside 3D files for accurate and efficient quotation.

Lead time depends on part complexity and order quantity. Standard prototypes can be delivered in 5-10 business days. For production runs, typical lead time is 2-4 weeks. Rush services are available for urgent projects.

Yes. We offer a full suite of post-processing services including anodizing, powder coating, plating, polishing, sandblasting, heat treatment, and assembly. We can deliver parts ready for final use.

We implement strict quality control at every stage: from material certification, in-process inspections (IPQC) to final quality checks using tools like CMM, calipers, and micrometers. First Article Inspection (FAI) reports and material certifications are provided with shipments.

Client IP protection is our top priority. We are willing to sign Non-Disclosure Agreements (NDAs) and have secure data management systems in place. Your drawings and designs will never be shared with third parties.

We focus on delivering high-quality CNC machined parts with efficient production to meet your exact requirements.