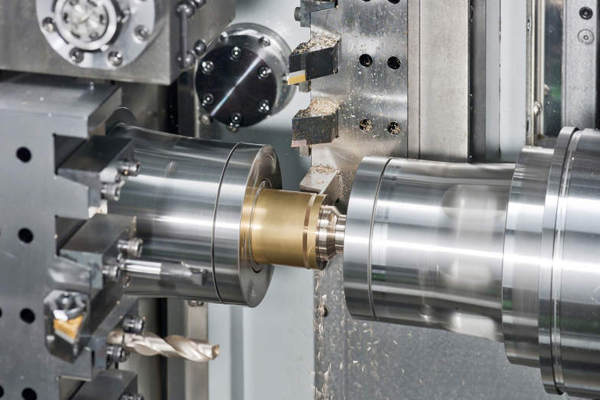

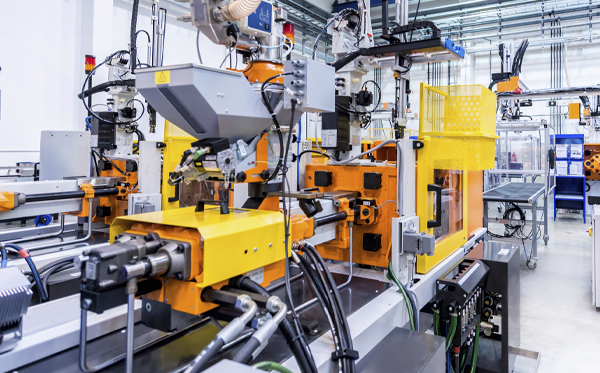

We are a professional CNC machining manufacturer with our own workshop and production equipment, focusing on custom, non-standard parts for global B2B customers. All projects are manufactured strictly according to customer-provided drawings or technical specifications, supporting flexible quantities from prototyping and small batches to stable mass production.

View More

We provide custom CNC machining services for metal and plastic parts, supporting both prototyping and low-to-medium volume production.

Our capabilities cover CNC milling, turning, multi-axis machining, and secondary processes to meet diverse custom manufacturing needs.

Each project follows strict quality control procedures, from material inspection to final measurement, ensuring consistent precision.

We work in accordance with international manufacturing standards and provide inspection reports based on customer requirements.

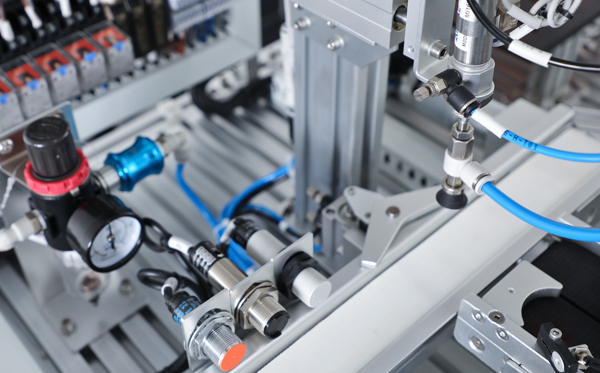

We provide custom CNC manufacturing services for a wide range of industries and applications. All parts are produced according to customer drawings and technical requirements.

High-precision milling and turning for custom metal and plastic parts, based on customer drawings.

Suitable for complex geometries and tight tolerances, reducing secondary operations.

Custom cutting, bending, welding, and assembly for industrial sheet metal parts.

Precision cutting and marking for metal and non-metal materials.

Anodizing, powder coating, plating, and polishing based on functional requirements.

Fast turnaround for prototypes and low-volume production to support product development.

Quick Quote Within 8 hours, 24-Hours Processing, Global Fast Delivery Service

Upload 2D/3D drawings or technical files.

Our engineers evaluate manufacturability and specifications.

We provide a clear quotation and lead time.

Parts are manufactured under strict quality control.

Finished parts are inspected and shipped as required.

We can manufacture your prototypes and parts out of almost any material that can be purchased on the open market. If you submit a special request, we can use a specific material that you provide. Below are the high-quality materials we commonly use in our custom parts.

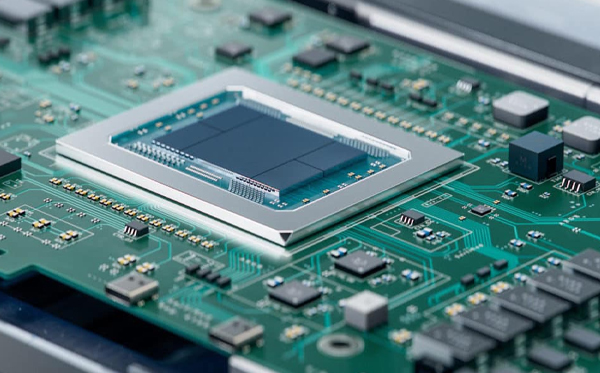

Our custom CNC machining services support clients from various industries:

We specialize in multi-axis CNC machining (3-axis, 4-axis, 5-axis) and can achieve standard tolerances of ±0.02mm (±0.001"), with tighter tolerances available upon request. We work with a wide range of metals and engineering plastics.

We accept STEP, IGES, X_T, SLDPRT, and DWG/DXF files. 2D drawings with critical dimensions and tolerances are highly recommended alongside 3D files for accurate and efficient quotation.

Lead time depends on part complexity and order quantity. Standard prototypes can be delivered in 5-10 business days. For production runs, typical lead time is 2-4 weeks. Rush services are available for urgent projects.

Yes. We offer a full suite of post-processing services including anodizing, powder coating, plating, polishing, sandblasting, heat treatment, and assembly. We can deliver parts ready for final use.

We implement strict quality control at every stage: from material certification, in-process inspections (IPQC) to final quality checks using tools like CMM, calipers, and micrometers. First Article Inspection (FAI) reports and material certifications are provided with shipments.

Client IP protection is our top priority. We are willing to sign Non-Disclosure Agreements (NDAs) and have secure data management systems in place. Your drawings and designs will never be shared with third parties.

We focus on delivering high-quality CNC machined parts with efficient production to meet your exact requirements.